Understanding Ecoating in the West Midlands

What is Ecoating and How Does It Work?

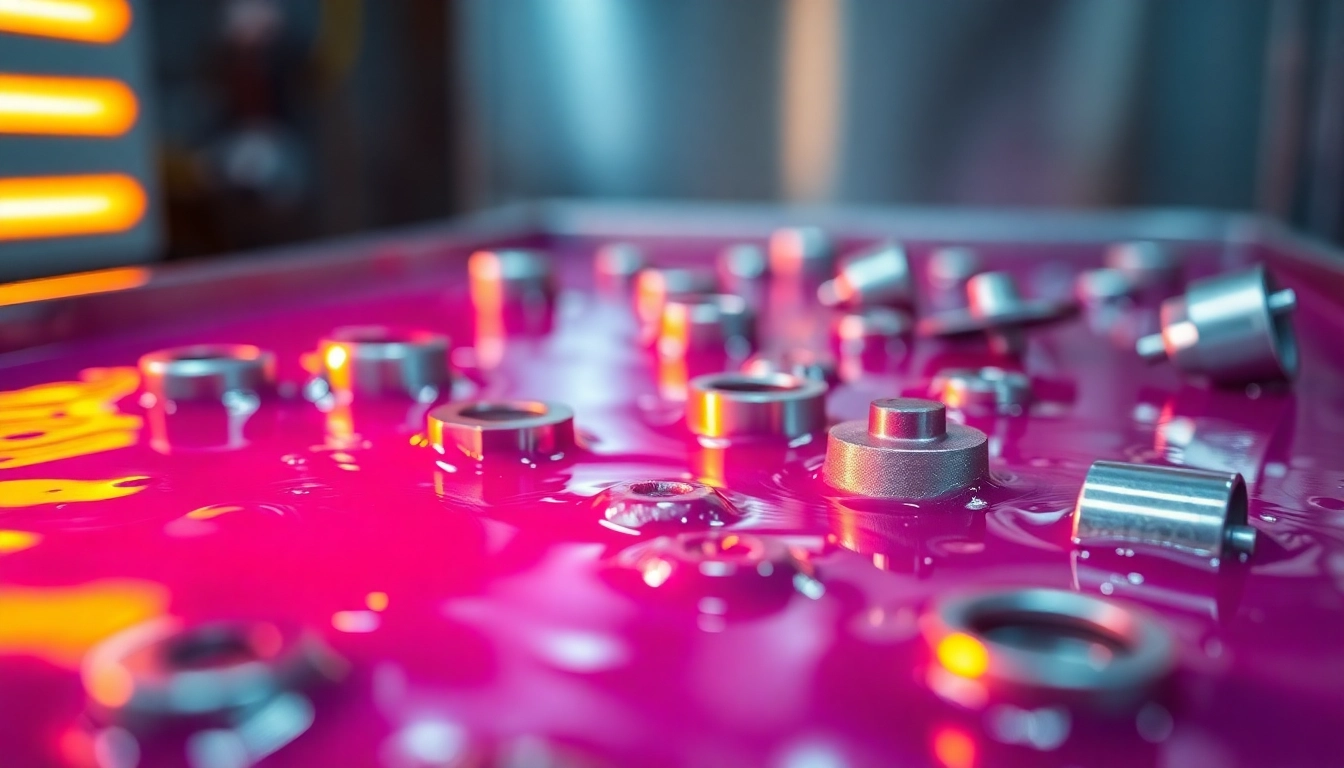

Ecoating, also known as electrophoretic deposition or e-coating, is a revolutionary painting technique applied to conductive substrates. This process involves immersing an object in a paint solution containing charged particles. When a direct current is applied, the charged particles migrate and deposit themselves onto the substrate, creating a uniform and durable finish. The primary advantage of this method is its ability to coat complex geometries and hard-to-reach areas, providing excellent coverage and protection.

The process starts with surface preparation, where the substrate is cleaned to remove contaminants. Once the substrate is submerged in the e-coating bath, electrical currents facilitate the migration of paint particles, forming a layer that adheres tightly to the surface. This method is particularly beneficial in ecoating west midlands manufacturers, where precision and quality are paramount.

Benefits of Ecoating for Various Industries

Ecoating offers several advantages across various industries, including automotive, aerospace, and manufacturing:

- Corrosion Resistance: The e-coat provides superior protection against corrosion and rust, extending the lifespan of components exposed to harsh environments.

- Uniform Thickness: The nature of the deposition process ensures a consistent coat, vital for parts requiring exact specifications.

- Environmental Compliance: Ecoating is often more environmentally friendly than traditional coating processes, as it uses water-based paints and generates less volatile organic compound (VOC) emissions.

Common Applications of Ecoating in the West Midlands

In the West Midlands, ecoating is applied across diverse fields:

- Automotive Components: Essential for parts such as chassis, frames, and various brackets.

- Aerospace: Used for critical aerospace components that demand lightweight and high-performance materials.

- Architectural Applications: Employed in the construction industry for metal parts that need enhancement against weathering and decay.

Key Advantages of Ecoating Compared to Traditional Coating Methods

Durability and Corrosion Resistance

One of the most compelling reasons to choose ecoating is its remarkable durability when compared to conventional methods. Traditional painting can lead to uneven coats that are susceptible to chipping and wear. In contrast, ecoating provides a robust barrier against corrosion by ensuring that every edge and crevice is protected. This is paramount in sectors such as automotive and industrial equipment where components are regularly exposed to corrosive elements.

Environmental and Economic Benefits

The ecoating process is less harmful to the environment. With water-based paints and reduced VOC emissions, it aligns well with the growing emphasis on sustainability in manufacturing. Economically, the durability of ecoated products leads to reduced maintenance costs over time, making it a wise investment for many industries.

Enhanced Aesthetic Appeal of Coated Products

Ecoating not only provides functional benefits but also enhances the visual appeal of products. With the ability to apply various colors and finishes uniformly, companies can ensure their products are not only durable but also attractive. This aesthetic value is particularly important in consumer-facing industries where appearance can significantly influence purchasing decisions.

Choosing the Right Ecoating Service Provider

Assessing Experience and Expertise

When selecting an ecoating service provider, assessing their experience in the field is crucial. Look for companies that demonstrate extensive industry knowledge and a proven track record of successful projects. Validation through certifications and adherence to industry standards can further assure clients of the quality and reliability of the service.

Evaluating Customer Reviews and Case Studies

Customer feedback is invaluable in understanding the effectiveness of an ecoating provider. Request case studies or testimonials that showcase previous work. A provider’s ability to communicate their process and results transparently can also indicate their level of professionalism and customer service.

Comparing Pricing and Service Offerings

Pricing can vary significantly among ecoating service providers. While cost should not be the sole factor, it’s essential to compare what is included in each package. Services may range from basic ecoating to advanced finishing processes. Understanding these offerings can help in making a well-informed decision that balances quality with cost.

Ecoating Process: What to Expect During Application

Preparation of Substrates for Ecoating

Preparation is a critical step in the ecoating process. It involves cleaning the surfaces of substrates to remove dirt, oil, and oxidation. This can be achieved through various methods such as sandblasting, chemical cleaning, or degreasing. Proper surface preparation ensures optimal adhesion and the longevity of the coating.

Electrophoretic Deposition Techniques

Once the substrate is prepared, the actual ecoating process begins. The immersion of the parts in the coating solution and the establishment of the electrical current follows preparing the applications. One interesting aspect of electrophoretic deposition is that the thickness of the coating can be controlled by adjusting the current and immersion time, allowing for customization to meet specific requirements.

Post-Application Finishing and Quality Control

Post-application steps include curing the coated parts, typically through heat or ultraviolet light, to enhance durability. Quality control measures, including visual inspections, thickness measurements, and adherence tests, must follow to ensure that the coated items meet all specified standards. This step is crucial in confirming the integrity and performance of the ecoated products.

Future Trends in Ecoating Technologies in the West Midlands

Innovations Aiming for Sustainability

The future of ecoating in the West Midlands is pivoting towards greater sustainability. New technologies are being invested in to develop eco-friendly coatings that minimize environmental impact while maintaining product performance. Innovation is leading to the integration of non-toxic materials and recycling technologies.

Integration with Automation and Smart Systems

The adoption of automation in ecoating processes is on the rise, increasing efficiency and reducing labor costs. Smart systems that monitor and control the coating process in real-time to ensure uniform application and optimal conditions are becoming popular strategies for enhancing operational effectiveness.

Expanding Applications in Emerging Markets

As industries continue to evolve, ecoating applications are expanding into new sectors, such as renewable energy, electronics, and biomedicine. This growth presents vast opportunities for manufacturers in the West Midlands to innovate and tap into emerging markets where high-quality coating is essential.