Introduction to Epoxy Prepregs

In the arena of advanced manufacturing, epoxy prepregs have emerged as a critical composite material, enabling the production of high-performance components across various industries. This article explores the intricacies of epoxy prepregs, delving into their composition, applications, advantages, challenges, best practices, and future trends. By understanding these elements, engineers and manufacturers can leverage epoxy prepregs to enhance their product quality and performance.

What Are Epoxy Prepregs?

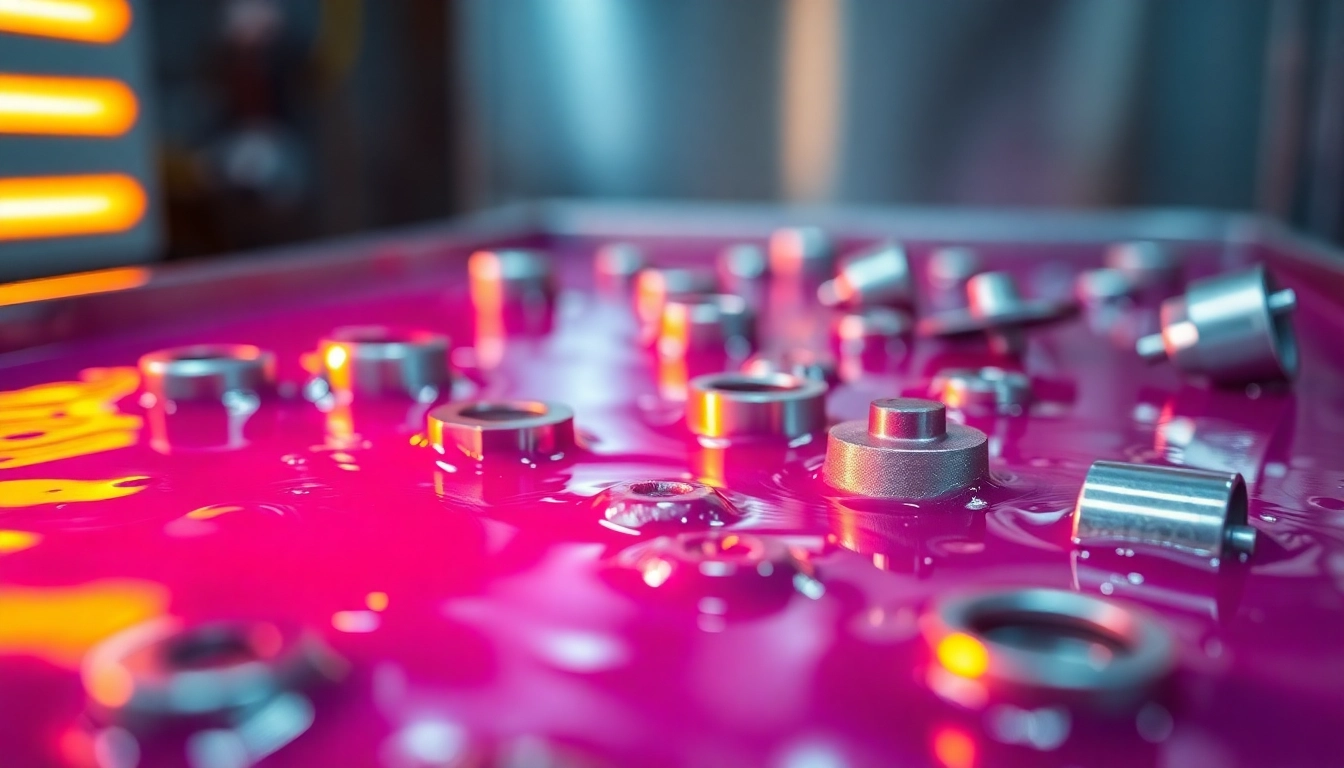

Epoxy prepregs, short for pre-impregnated materials, comprise reinforcement fibers that are pre-impregnated with a thermosetting resin, specifically epoxy resin. This process allows for easy handling and moldability, facilitating the manufacturing of complex shapes and structures. The fibers, which may include carbon, glass, or aramid, are coated with the epoxy resin in a controlled environment, allowing for a precise ratio of fiber to resin that optimizes performance characteristics such as strength, stiffness, and toughness.

History and Development of Prepreg Technology

The technology behind the development of epoxy prepregs has its roots in the mid-20th century, as aerospace and automotive industries began to explore novel materials that could offer enhanced properties over traditional metals. The capability to combine fibers with resin ushered in a new era of composite materials. Over the decades, advancements in polymer chemistry and fiber technology have significantly improved the performance and versatility of epoxy prepregs, leading to their widespread adoption in high-performance applications.

Key Components of Epoxy Prepregs

The effectiveness of epoxy prepregs lies in their key components: the epoxy resin and the reinforcement fibers. The epoxy resin serves as the matrix material, providing adhesive properties and structural integrity once cured. Reinforcement fibers, on the other hand, offer tensile strength and stiffness, crucial for the mechanical performance of the final product. The combination of these materials is meticulously engineered to achieve desired mechanical and thermal properties while also considering the application requirements, such as load, environmental exposure, and fatigue resistance.

Applications of Epoxy Prepregs across Industries

Epoxy prepregs have found utility in various sectors, with distinct applications tailored to meet the specific demands of each industry. Their unique properties, such as lightweight, strength, and resistance to environmental factors, make them ideal candidates for manufacturing advanced components.

Aerospace and Defense Standards

In the aerospace and defense industries, the rigorous standards for materials require components that can withstand extreme conditions while maintaining structural integrity. Epoxy prepregs are extensively utilized in the manufacturing of aircraft wings, fuselages, and other critical components due to their high strength-to-weight ratio and excellent fatigue resistance. Manufacturers often optimize fiber architecture and resin formulations to comply with stringent safety and performance standards set by regulatory bodies.

Automotive Manufacturing Improvements

The automotive industry is increasingly turning to epoxy prepregs for lightweight structural components to enhance fuel efficiency and reduce emissions. Applications include body panels, structural reinforcements, and interior components. Using epoxy prepregs allows manufacturers to produce parts that are not only lighter but also provide superior impact resistance and durability against environmental conditions. This shift is vital for meeting global regulations aimed at reducing carbon footprints and improving vehicle performance.

Sporting Equipment Innovations

In the realm of sporting equipment, epoxy prepregs have revolutionized product design. High-performance bicycles, tennis rackets, and golf clubs leverage the properties of prepregs for enhanced performance and durability. The ability to mold complex shapes with precise control over material properties allows manufacturers to create equipment that optimally balances weight, strength, and stiffness, providing athletes with a competitive edge.

Advantages of Using Epoxy Prepregs

Utilizing epoxy prepregs presents numerous advantages that significantly impact manufacturing processes and end-product performance. These benefits resonate across multiple applications and industries, enhancing the overall credibility of epoxy prepregs as a material of choice.

Enhanced Strength and Durability

One of the primary advantages of epoxy prepregs is their remarkable strength and durability. The combination of high-modulus fibers with epoxy resin results in a composite material that can withstand heavy loads and dynamic stress. This strength translates to extended product lifespan and reduced maintenance needs, making epoxy prepregs a cost-effective option in the long term.

Weight Reduction Benefits

The lightweight nature of epoxy prepregs is crucial in applications where weight plays a pivotal role, such as aerospace and automotive industries. By switching to epoxy prepreg components, manufacturers can achieve significant weight savings, leading to improved fuel efficiency and performance. This weight reduction is particularly beneficial in high-speed applications, where every ounce matters.

Consistency in Quality and Performance

Another compelling advantage of using epoxy prepregs is the consistency they offer in terms of quality and mechanical performance. Since the resin is applied in a controlled environment, variations in curing and material properties are minimized. This reliability ensures that each part meets the required specifications and standards, reducing the occurrence of defects and failures during operation.

Challenges in Utilizing Epoxy Prepregs

Despite their numerous advantages, working with epoxy prepregs is not without challenges. Manufacturers must navigate various hurdles that can impact production efficiency and cost.

Storage and Shelf Life Considerations

Epoxy prepregs require careful storage to maintain their properties. They are typically stored at low temperatures to preserve the resin’s reactivity. Once thawed, the shelf life may be limited, necessitating precise inventory management to prevent wastage. Manufacturers must establish protocols for the handling, storage, and use of epoxy prepregs to maximize their shelf life and ensure optimal performance in production.

Processing and Handling Difficulties

The processing of epoxy prepregs can pose challenges, particularly during the curing phase. Ensuring uniform heat distribution and achieving the necessary pressure is critical to avoid inconsistencies in the final product. Implementing sophisticated heating systems and employing skilled technicians familiar with the intricacies of prepreg processing can mitigate these issues, facilitating smoother manufacturing operations.

Cost Implications in Production

While epoxy prepregs offer significant benefits, the initial costs associated with their use can be higher than traditional materials. Factors such as material pricing, processing equipment, and labor costs contribute to the overall expenditure. Manufacturers must conduct thorough cost-benefit analyses to understand the financial implications and justify the investment in epoxy prepreg technology.

Best Practices for Working with Epoxy Prepregs

To harness the full potential of epoxy prepregs, manufacturers should adopt best practices that enhance product quality and production efficiency. These practices are critical in ensuring that the benefits of epoxy prepregs outweigh the challenges.

Preparation and Curing Techniques

Effective preparation and curing techniques are paramount in the use of epoxy prepregs. Adhering strictly to the specified curing temperatures and times is essential for achieving optimal properties in the final product. Employing a calibrated thermal cycling process can improve the mechanical performance of the cured prepreg, ensuring that it meets the necessary performance criteria.

Quality Control and Testing Methods

Implementing rigorous quality control measures is vital for maintaining the integrity of epoxy prepreg components. This includes routine inspection and testing methods such as ultrasonic testing, visual inspection, and mechanical analysis to evaluate the properties of the cured product. By establishing robust testing protocols, manufacturers can identify potential issues early in the manufacturing process and ensure compliance with industry standards.

Future Trends in Prepreg Technology

The future of epoxy prepregs is promising, with ongoing advancements in materials science and manufacturing technology. Emerging trends include the development of bio-based resins, enhanced processing techniques, and improvements in fiber-reinforcement technologies. These innovations are expected to lead to even greater performance characteristics, reduced environmental impact, and wider applications across various sectors.